OEM Manufacturer Glass Flat Lens - Precision injection molding optical lens mold – Zhantuo Optical Lens

OEM Manufacturer Glass Flat Lens - Precision injection molding optical lens mold – Zhantuo Optical Lens Detail:

| Specification | |

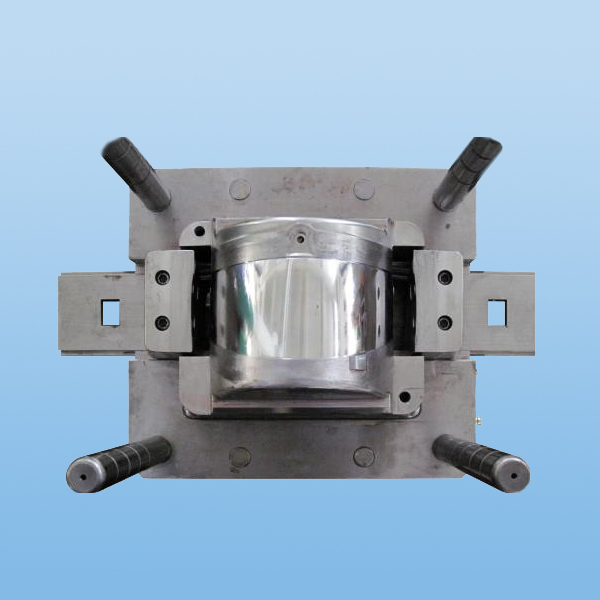

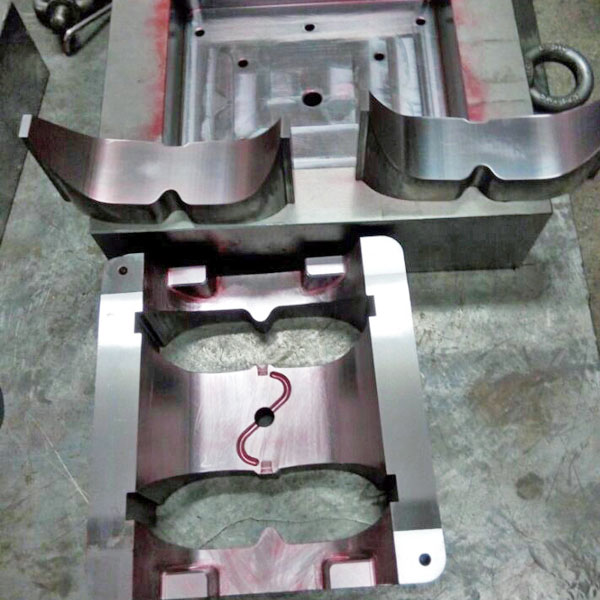

| Product Name | Precision injection molding optical lens mold |

| Product Number | H222MJ |

| Type | Mold Manufacturing |

| Using | Helmet Lens Mold, Ophthalmic Lens Mold, Sunglasses Glasses Mold, Myopic Lens Mold, Presbyopic Lens Mold, Industrial Eyeglasses Mold, HUD Lens Mold, Eye Protection Lens Mold, Optical Lens Mold, TV Lens Mold, VR Lens Mold, LED Optical Lens Mold, Fresnel Lens molds, Laser Lens molds, Ski lens Molds, Swimming Lens Molds, Precision Injection Molding Optical Lens Molds, Transparent Mask Molds, Goggle Molds, PC Lens Molds, PMMA Lens Molds, Hemispherical Lens Molds, Spherical Lens Molds, Aspherical Mirror Lens mold, Double Curved Lens Mold, Bent Lens Mold |

| Color | Mirror Finish |

| Logo Design | Customized |

| Shape Design | OEM/ODM |

| Size | OEM/ODM |

| Packing | Fumigation Wood Boxes |

| Materials | Die steel: S136, S136H, NAK80, P20, 718H, etc |

| Production Technology | Die design, Die parting, CNC, Wire-electrode cutting, Lathe, Milling, Grinding, Electric spark, Polishing, Assembly and Trial mold. |

| Testing standard | GB T 12554-1990,DME Standard,HASCO Standard |

Product Feature:

With our complete molding process equipment, precision grinding and polishing equipment and mold design & technical team, Zhantuo Optics own mold room can rapidly develop various optical lens molds and lens peripheral fitting molds with the injection molding department and undertake various injection molds. Production.

Mold parameters:

Steel: using high-quality mirror steel, Lung Kee, ASSAB S136 S136H NAK80 45 # quenched 60 # quenched P20H 718H 2316 for your choice;

Molds: DME, HASCO, FUTABA, LKM;

Cooling system: optimized design of circulating water, increase production efficiency, reduce your costs;

Mid-term treatment: conditioning, increase hardness;

Post-processing: vacuum heat treatment, azotizing;

Die life: P20 normal use of not less than 300,000 beer times, S136 normal use up to 1 million beer times.

Mold acceptance and delivery:

★ According to the agreed delivery date;

★ The mold size determined by the customer;

★ Customer confirmed technical process plan;

★ Mold design drawings and electronic documents;

★ According to customer requirements, debugging until achieve to product assembly qualified, can be formally produced;

★ Surface of testing sample without any defects such as deformation, shrinkage, or injection hole affecting the vision, and pass the optical test standards specified by the customer.

Product detail pictures:

Related Product Guide:

Difference Between Contact Lens and Optical Glass

Qualities All Optical Lens Manufacturers Should Possess

We stay with the basic principle of "quality initially, services first, steady improvement and innovation to fulfill the customers" for your management and "zero defect, zero complaints" as the quality objective. To perfect our company, we give the goods while using the good high-quality at the reasonable selling price for OEM Manufacturer Glass Flat Lens - Precision injection molding optical lens mold – Zhantuo Optical Lens, The product will supply to all over the world, such as: Vietnam, Durban, Canada, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!