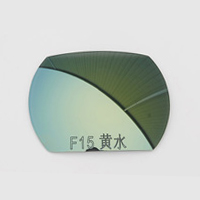

F15 Green Silver

| Specification | |

| Product Name | F15 Green Silver |

| Product Number | F15 Green Silver |

| Type | Lens processing |

| Using | Applicable to optical lens and PC, PMMA, PET, PVC, POM and other plastic products on the surface of the lens coating processing, environmental protection vacuum plating processing, optical coating processing, processing film color plating: REVO coating, AR platinum coating, multicolor mercury plating, General mercury plating, etc. Dielectric plating: AR single-layer anti-reflection coating, multi-layer anti-reflection coating, splitting film, reflective film, high reflective film, AF waterproofing film, anti-fingerprint film, anti-blue film, UV film. |

| Color | Transparent/Custom color |

| Logo Design | Customized |

| Shape Design | OEM/ODM |

| Size | OEM/ODM |

| Packing | Protective film packaging, Layered code box |

| Materials | Silicon monoxide, zinc sulfide, aluminum oxide, silver oxide, copper, gold, silicone oil, etc. |

| Production Technology | Vacuum plating, Ion plating |

| Testing standard | GB/T 12609,ASTM D3359,ASTM B456 |

Product Feature:

Zhantuo Optics is equipped with a completely automatic cleaning, strengthening, anti-fog, dyeing and drying processing line. It is used for multitudinous post-processing processing of injection molded lenses, which the hardening process can pass the SGS falling ball test, falling sand test, and impact resistance test.

We have set up vacuum plating department, according to different requirements of customers to develop a variety of plating color and reflection, anti-reflective, anti-fingerprint, anti-blue, UV400 and other functional plating dielectric film.

Strengthened: enhanced lens surface hardness, scratch resistance, abrasion resistance, and enhanced plating adhesion;

Anti-fog: prevent or avoid condensation of water mist;

Dyeing: reduce light intensity, improve vision, and decorate;

Electroplating: anti-reflection, reflective, filter, polarization, protection and decoration.